Summary:When specifying a PU welded timing belt for high-speed or heavy-load applications, several critical considerations should be taken into account to ensure optimal performance and longevity. Here are key factors to consider:

Load Capacity: Conduct a t......

When specifying a PU welded timing belt for high-speed or heavy-load applications, several critical considerations should be taken into account to ensure optimal performance and longevity. Here are key factors to consider:

Load Capacity: Conduct a thorough analysis of the dynamic and static loads the timing belt will encounter during operation, considering any potential variations or shock loads.

Employ engineering calculations and simulations to precisely determine the maximum loads, and choose a PU welded timing belt with a load capacity that surpasses these calculated values, providing a substantial safety margin.

Pitch and Tooth Profile: Delve into the specific power transmission requirements of the application.

Consider the nuances of different pitches and tooth profiles, taking into account their impact on torque transmission, engagement, and overall system performance.

Belt Width: Explore the trade-offs associated with varying belt widths in relation to load distribution and system inertia.

Conduct a detailed analysis to strike a balance between the benefits of wider belts in load distribution and the potential drawbacks related to increased inertia, particularly in applications where high-speed dynamics are critical.

Tensile Strength: Scrutinize the tensile strength of the PU material used in the timing belt.

Factor in the anticipated tensile forces the belt will experience under heavy loads, and select a timing belt with a robust tensile strength to mitigate the risk of elongation and premature failure.

Coefficient of Friction: Dive into the specifics of the coefficient of friction of the PU material, considering the operational conditions.

Recognize that a lower coefficient of friction not only enhances efficiency but also plays a crucial role in reducing heat generation and minimizing wear, particularly in high-speed or heavy-load applications.

Backing Material: Evaluate the backing material's properties with a focus on flexibility and resistance to deformation.

Understand the role of a flexible backing material in accommodating bending around pulleys, and emphasize the need for resistance to deformation to ensure stability and consistent performance under heavy loads.

Temperature Resistance: Thoroughly analyze the expected operating temperature range.

Acknowledge the potential heat generation in high-speed applications and select a PU material with exceptional temperature resistance to prevent thermal degradation and maintain mechanical integrity over time.

Dynamic Performance: Conduct a detailed assessment of the timing belt's dynamic characteristics, emphasizing its ability to operate seamlessly at high speeds.

Prioritize features such as reduced vibration and noise, recognizing their critical role in preserving overall system efficiency and integrity, especially in demanding high-speed applications.

Pulley and Sprocket Compatibility: Ensure meticulous compatibility between the timing belt and the pulleys or sprockets within the system.

Recognize that even slight misalignments or mismatches can lead to uneven wear, increased friction, and decreased efficiency, underscoring the importance of precise engineering and alignment throughout the system.

Installation and Maintenance: Delve into the intricacies of the installation process and any maintenance requirements associated with the timing belt.

Emphasize the need for a well-designed system that facilitates straightforward installation procedures and demands minimal maintenance, ultimately contributing to overall efficiency and minimizing downtime.

Environmental Factors: Identify and thoroughly assess any environmental factors that might impact the timing belt, such as exposure to chemicals, moisture, or abrasive substances.

Prioritize the selection of a PU material that exhibits resistance to these environmental challenges, ensuring the timing belt's longevity and sustained performance in diverse and demanding conditions.

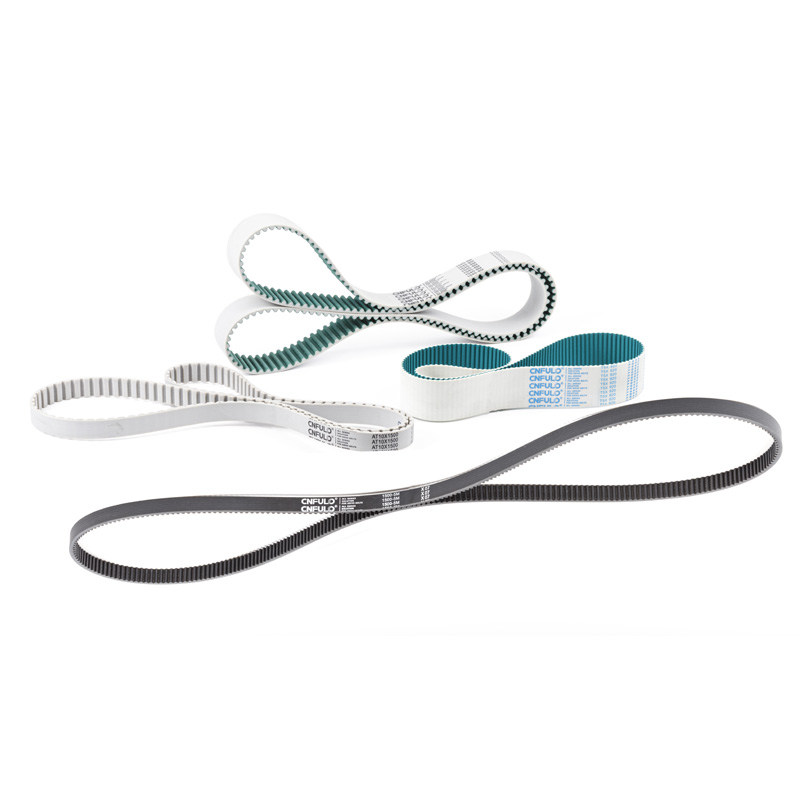

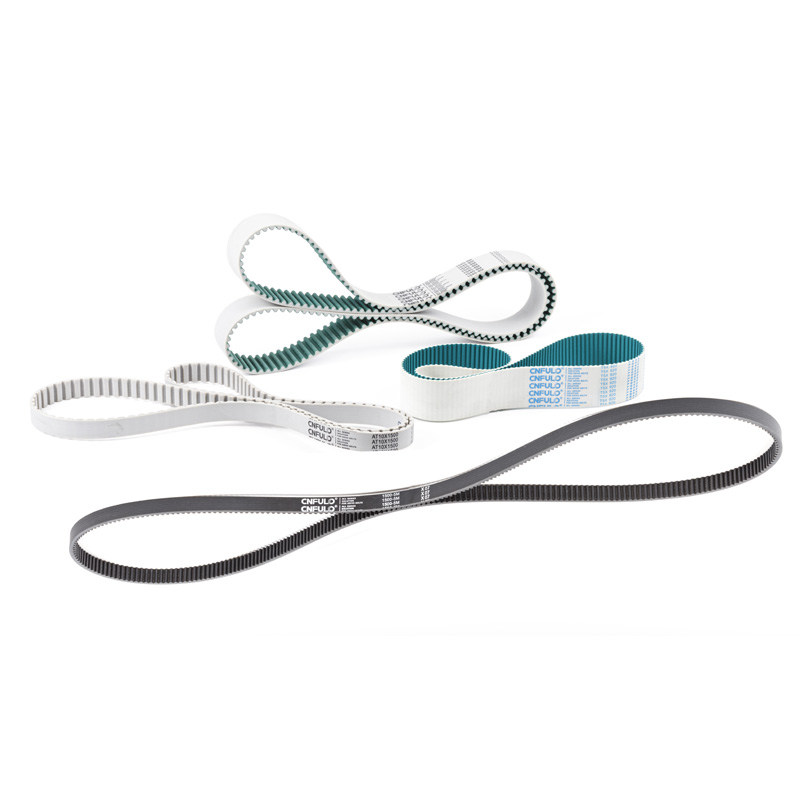

PU Welded Timing Belt