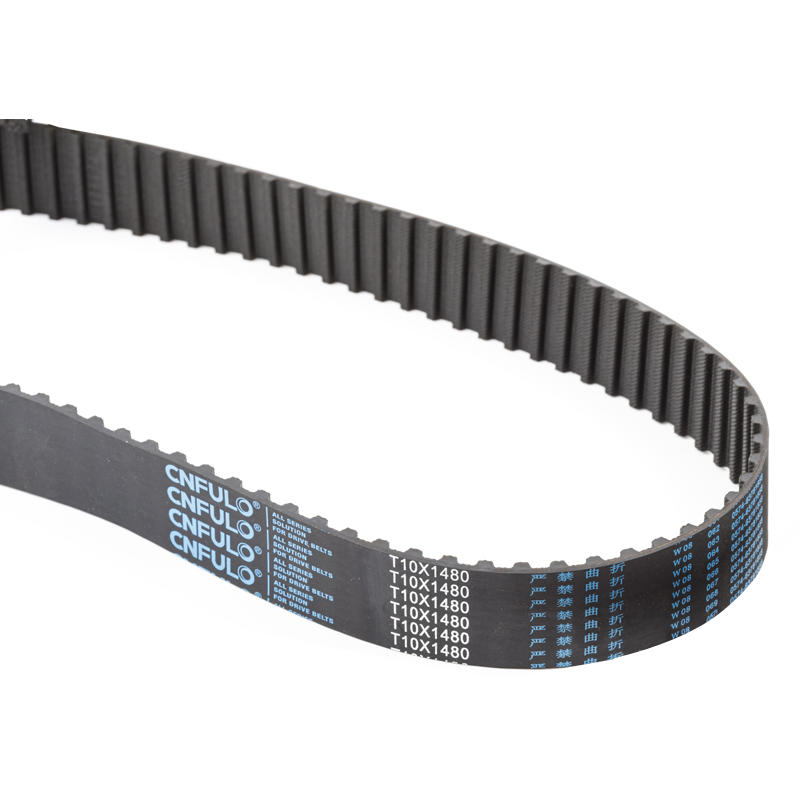

Ningbo Fulong Synchronous Belt Co., Ltd. is a famous China Industrial Synchronous Belts Suppliers and Industrial Synchronous Belts Factory, located in Longshan Town, Cixi City, Zhejiang Province. It was founded in 1984. It is the earliest enterprise engaged in the research and development, production and sales of rubber synchronous belts in China.

read more

Latest News

22-07-2024

Industry News

Use Tensioning Tools: Employ dedicated tensioning tools designed specifically for industrial rubber flat belts to achieve accurate and consistent tension levels. These tools range from mechanical tens...

read more15-07-2024

Industry News

Noise Levels: Industrial variable speed belts are renowned for their ability to operate quietly compared to alternative transmission systems like chain drives or gear transmissions. The primary reason...

read more08-07-2024

Industry News

Strength and Durability: Carbon steel timing pulleys offer superior mechanical properties, including high tensile strength and resistance to deformation. These characteristics ensure that the pulleys ...

read more01-07-2024

Industry News

Installing and adjusting carbon steel timing pulleys correctly is crucial for achieving optimal performance. Here’s a step-by-step guide: Prepare the Workspace: Before starting, ensure your workspace ...

read more24-06-2024

Industry News

Selecting power transmission belts for high-speed applications involves several critical considerations to ensure optimal performance and longevity. Here are some key factors to keep in mind: Belt Mat...

read more17-06-2024

Industry News

When a timing belt fails, several critical engine components can be affected. Here are the key parts that might be impacted: Valves: When a timing belt fails, the synchronization between the camshaft ...

read more